Manganese Steel Plate Hadfield Grade TENSAMANG™ from ...

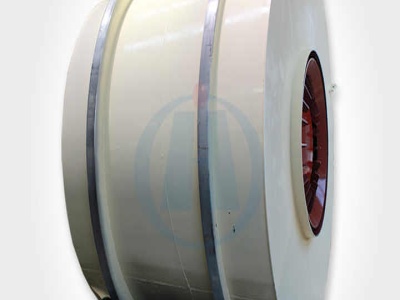

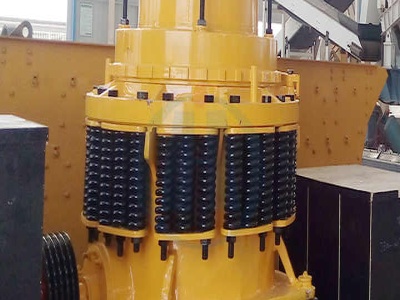

In terms of its properties, Hadfield Grade Tensamang manganese steel is both a nonmagnetic and abrasion resistant steel plating product, making it the buyer's choice for magnet bottoms and separator drums. Our 1114% Hadfield Grade Tensamang™ steel wear plate is heat treated to the point that it develops a hard surface.