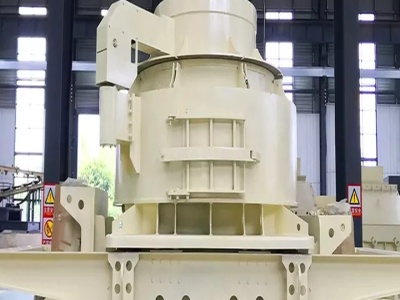

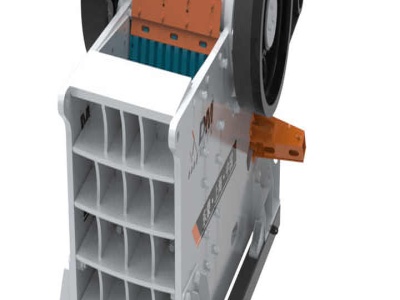

talc mining and processing

Talc processing machinery:talc grinding mill,crusher,talcum powder machinery grind talc into grainsTale production mill:ball mill,jet mill and roller mill for talc talc processing line Shanghai Intro Talc is one of the most important industrial minerals Talc is a common metamorphic mineral in .