SPONGE IRON PLANT

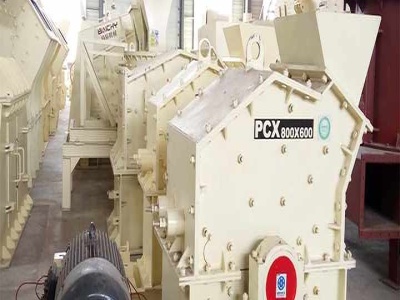

PROCESS FLOW CHART FOR MANUFACTURE OF SPONGE IRON Raw Material Feeding at ground hopper (Coal, Ore) Coal Over Size Crushing Screening Coal Bin Iron Ore Bin Screening Crushing Sized Iron Ore Over Size Limestone Bin Screening of mixed end product (Sponge Iron and unburnt coal) Indirect cooling in rotary cooler with water spray