standard lead flotation processing mantle

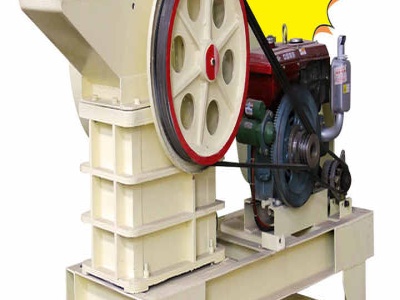

In ore beneficiation, flotation is a process in which valuable minerals are separated . to the grinding circuit where water is added and the ore is ground to the proper size. . The tailing from the lead flotation circuit is the feed to the zinc circuit. Live Chat