How To Make Raymond Mill Get More Fineness

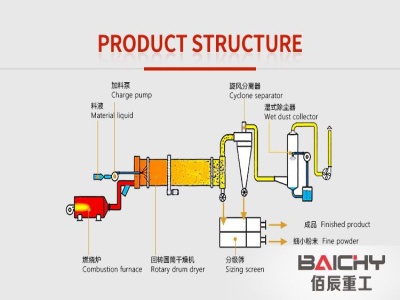

If you want to process the material with high fineness, you can switch to other equipment, such as highpressure grinding mill. The fineness of the equipment can reach the highest level, which is much higher than Raymond mill. Back:How To Reduce The Maintenance Cost Of Raymond Mill.