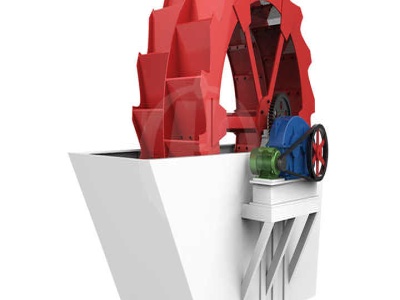

CONCRETE MIXER MACHINES | Mix cement efficiently with ...

These are specially designed 10/7 one bag (sack) type of mixer machine with lift and tilting drum which can also lift the mixed cement concrete mixture upto 5565 feet of height. This dual operation is very beneficial to customer cost wise and hence is very popular in small concreting jobs of 4 floors to 5 floors for slab work and other concreting needs of lowrise buildings.