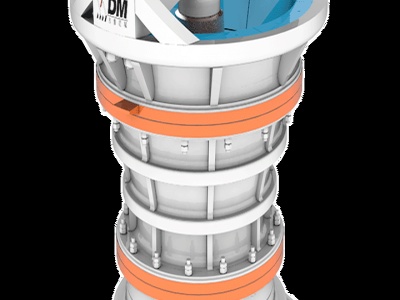

Zhengyuan Powder Engineering Equipment Co., Ltd

Application: 1. Used for classification, removal of contamination and deagglomeration for numerous kinds of material. ... where separating into the oversize part and the fine part is achieved by the centrifugal force and attraction force, the fine is collected and the oversize is discharged. ... be used with ball mill, Raymond mill ...