Froth Flotation Fundamental Principles Kawatra

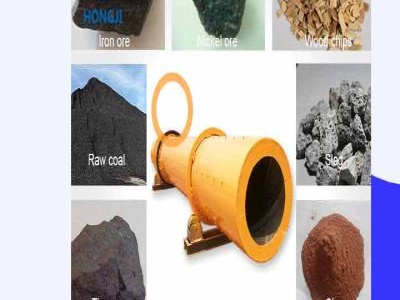

froth flotation of fly ash Solution for ore mining Station due to the volume of ash in the ponds. While most carbon removal processes operate on dry fly ash, Froth Flotation can .