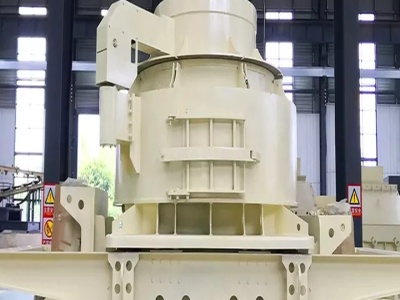

The Production Process Machine Information Systems

The production process is the method that businesses make products and services. A productive process is quite a fluid process. it will be analysed and tweaked as needed continually to make improvements in cost, speed and qualitiy. The main resources and stagesthat are involved to make up the production process are shown here below.