Is it Safe to grind aluminum, or not? Finishing

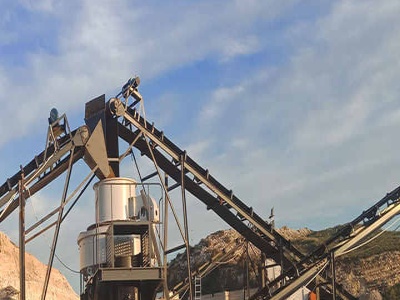

Safe to grind aluminum, or not? 2004. A. It is not cost effective to grind aluminum, even skim passes, as it clogs the wheel so much and so fast that it does not "cut".Going to a larger grit size and a very frangible resin will allow it to cut better, but you will go thru wheels very fast.