Examples of Condensation Introduction in Cement Plant ...

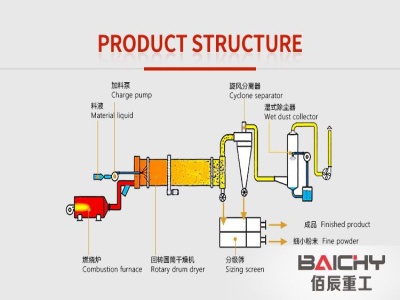

Production was found : a large bag filter pressure drop ; the grinding of cement temperature up to 150 ℃ production has been maintained by regularly changing the filter bag . Examples of low temperature B factory φ 3m × llm same as the cement mill with a cyclone separator flow grinding circle, using the air box bag filter .