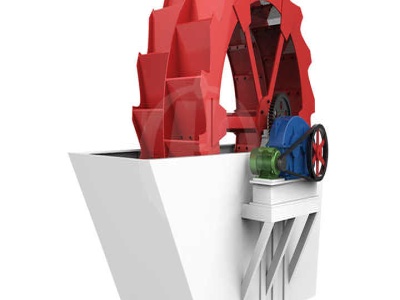

JC Series Jaw Crusher Luoyang Dahua

4. The bearing design ensures the big loading capacity and reliable operation of jaw crusher. 5. The design of toggle plate increases the stroke of lower chamber and processing capacity. 6. The integrated design of the motor base together with the main frame saves the installation space. 7.