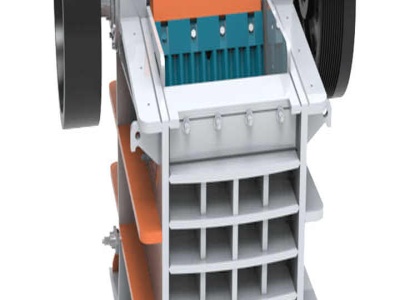

How to Improve the Service Life of Sand Crusher Machine

Thus, how to improve the service life of sand crusher machine? The new designed VSI sand making machine can produce good quality mechanical sand, which meets the standard of construction sand. The hardness and size of the stone shall meet the requirements of sand crusher machine.