iron ore processing plant design

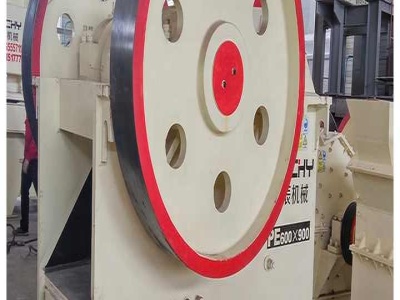

The Karara Iron Ore Project is an tons per annum (Mtpa) operation ... to the operating plant during construction, commissioning, and operation. ... 2A of the project because of its expertise in designing largescale iron ore processing...