Zinc: smelting, producing and classificationMetalpedia

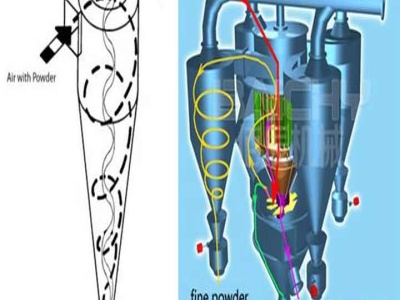

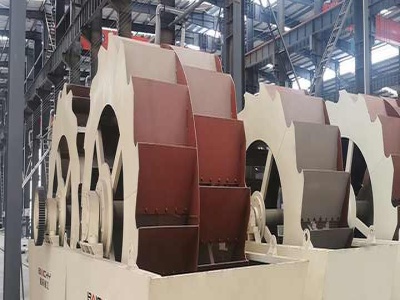

Zinc smelting. Zinc smelting is the process of converting zinc concentrates (ores that contain zinc) into pure zinc. The most common zinc concentrate processed is zinc sulfide, which is obtained by concentrating sphalerite using the froth flotation method.