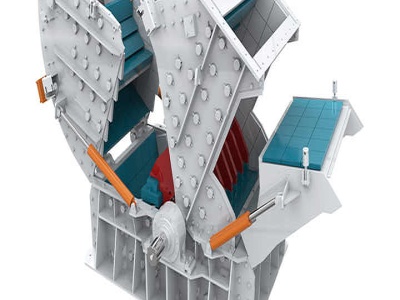

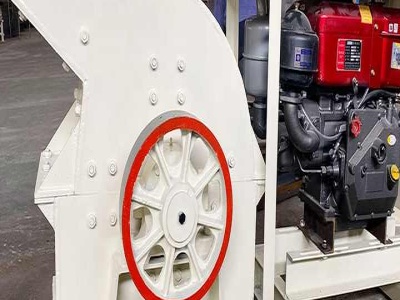

Cement crushing manufacture

cement Manufacture of cement There are four stages in the manufacture of portland cement: 1 crushing and grinding the raw materials, 2 blending the materials in the correct proportions, 3 burning the prepared mix in a kiln, and 4 grinding the burned product, known as clinker,together with some 5 percent of gypsum to control the time of set of ...