cement ball mill | tradekorea

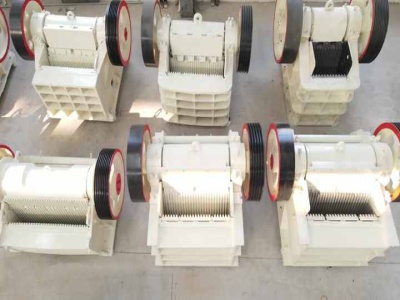

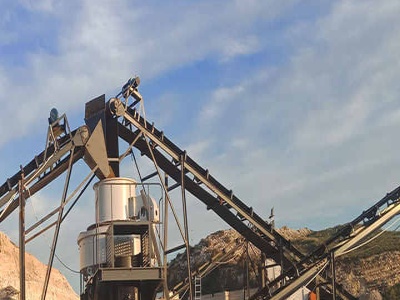

Keyword CEMENT MILL,CEMENT BALL MILL,GRINDING BALL MILL,BALL MILL MANUFACTURE. Description Send Inquiry Add Interests. 2 Henan Zhengzhou Mining Machinery Co.,Ltd. China Supplier Grade level3. Response Rate 0%. View Minisite. Ball mill Grinding machine for Stone/ Ore/ Coal/ Cement.