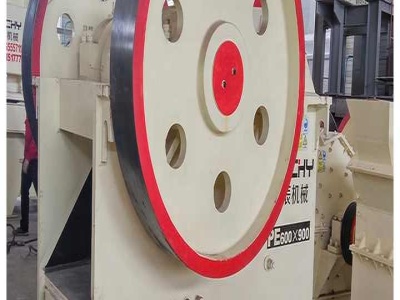

Mills and Crushers | Lab Synergy

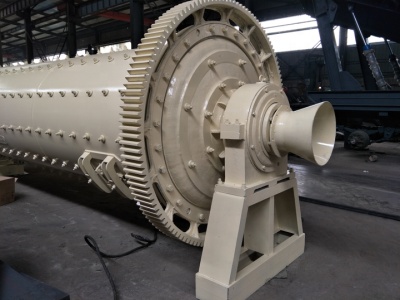

Planetary Ball Mills. Fritsch Ball Mills are perfectly designed for a variety of laboratory needs. These Ball Mills are ideal for wet and dry communition of hard, mediumhard, brittle and fibrous materials. They are capable of grinding down a few milligrams to several kilograms down into micron or nano range.