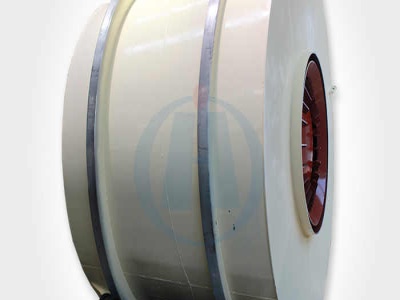

Wuma variable speed transmission,variable ratio gearbox

Variator. 1)High strength of variable gearbox: when reversely running with an impact load, it is reliable and able to precisely drive, without a recoil and with sufficient strength. 2)Large range of variable speed transmission: the range of speed variation is 5 ( its speed ratio can be varied between 1: and 1:). 3)High precision...