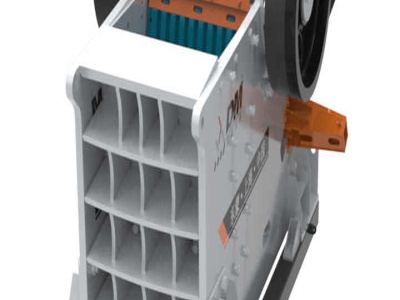

Rock Drilling and Blasting Professionals McCallum Rock ...

McCallum Rock Drilling specializes in rock drilling and blasting, primarily in Washington and Oregon. Our highly trained operators and blasters are among the most skilled in the industry.