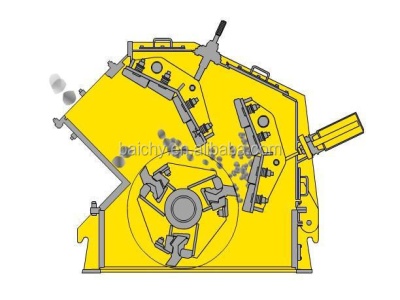

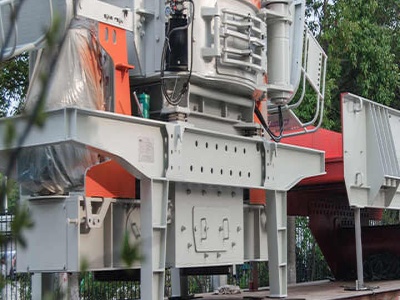

VERTICAL ROLLER MILL roller maintenance PROCEDURE

Cement Plant Maintenance Work Repairing of Vertical Roller Mills..... of Vertical Roller Mills, Shell Replacement Work, Reversals of Gear and Pinion, ... using casting process done using ceramic and aluminum material support.