Coal India Wikipedia

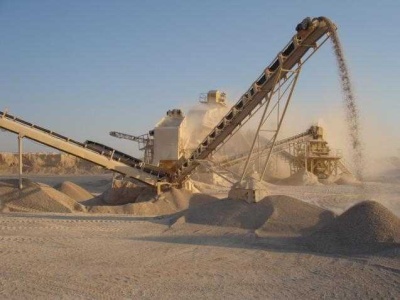

CIL is the largest coal producing company in the world. It produced MT (million tonne) coal during FY201516. Coal India operates through 81 mining areas in eight states in India. As on 1 April 2015, it has 430 coal mines out of which 175 are open cast, 227 are underground and 28 are mixed mines.