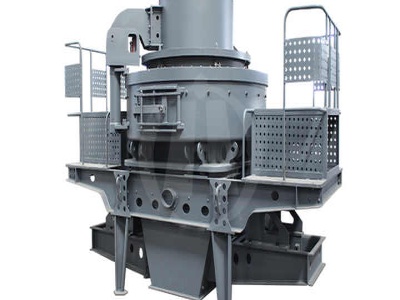

Grinding Mill

Ceramic Raw Materials Processing; Slag Processing; PRODUCT. More. MTW Series Trapezium Mill; MB5X Pendulous Hanging Grinding Mill; Vertical Roller Mill; LUM Ultrafine Vertical Mill; SCM Series Ultrafine Mill; Ball Mill; Hammer Mill; Coating machine; CASE. ... Chongming 6TPH SlagCement Grinding Plant; Iraq 60000TPY Gypsum Grinding Plant ...