Energy Efficiency and Saving in the Cement Industry ...

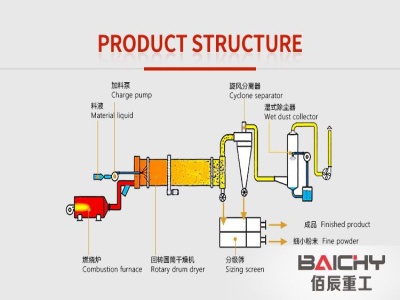

Wet cement production involves mixing raw materials (limestone and clay or loam) with water in order to produce slurry. Further in the process, water is evaporated from the homogenized mixture and this step in the production requires significant amounts of energy.