Calcium carbonate Essential Chemical Industry

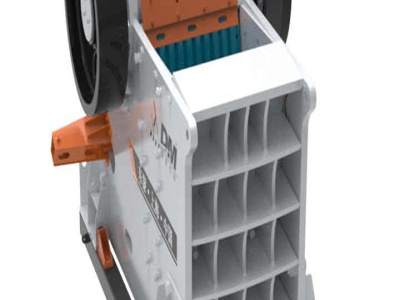

Limestone is also the main constituent of cement and concrete. In cement making. Cement is made by first mixing limestone and substances such as clays (which contain silica, alumina and iron(III) oxide) to a fine powder. The mixture is crushed and fed into a rotary kiln, which is an iron pipe, 6090 m long and approximately 6 m in diameter. The pipe is rotated and heated to about 1700 K by flame inside of it.