Jaw Crushers | McLanahan

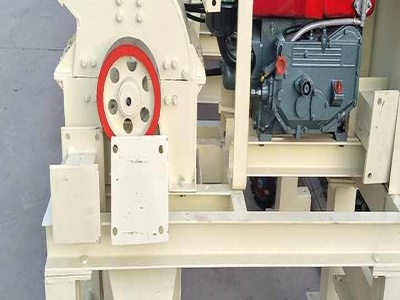

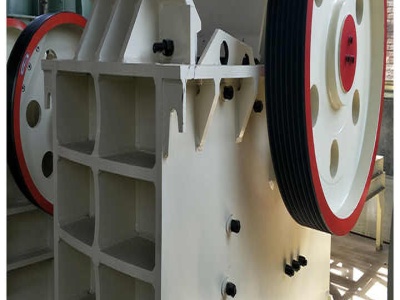

A toggle plate and tension rods hold the pitman tight near the bottom of the moving swing jaw. The toggle plate is designed to perform like a fuse and protect the crusher in the event that an uncrushable material enters the crushing chamber. As a rule, Jaw Crushers have a .