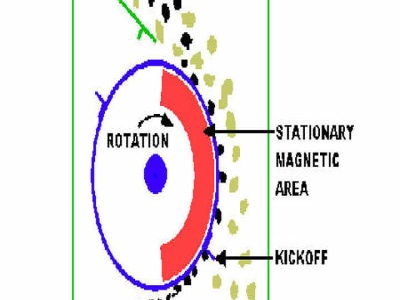

Binani Cement implements effective energy efficiency ...

Binani Cement implements effective energy efficiency measures . Binani Cement combats Global Warming for a better tomorrow by ensuring energy conservation Sets up three captive power plants and other new generation technologies to become energy efficient.