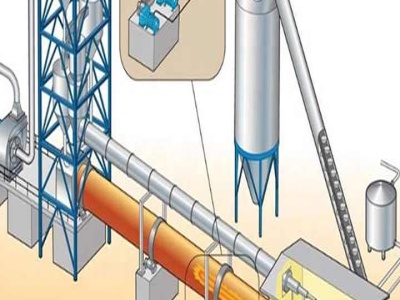

Your iron ore beneficiation solutions Mineral Technologies

Your iron ore beneficiation solutions Whether investing in a new project or optimising an existing plant, there are many hurdles to overcome including investment, licensing, infrastructure, recovery of minerals and marketing the