Low temperature cement grinding Page 1 of 1

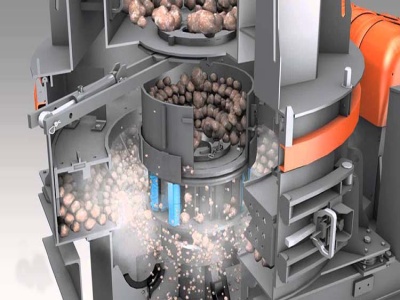

Re: Low temperature cement grinding. With the low residence time and low temperatures in vertical mills for cement grinding gypsum dehydration will not be completed. That might well affect the setting time, workability and compressive strength development of the cement. This is .