Cement Manufacturing Process | Phases | Flow Chart ...

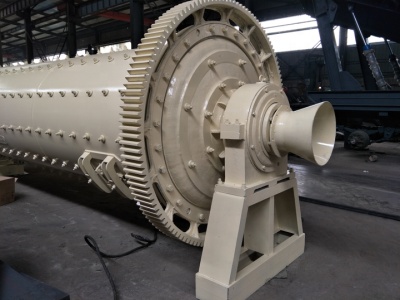

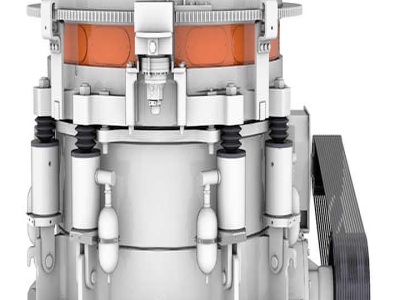

Aug 30, 2012· Raw mix is stored in a prehomogenization pile after grinding raw mix to fine powder. Cement Manufacturing Process Phase III: Preheating Raw Material. After final grinding, the material is ready to face the preheating chamber. Preheater chamber consists of series of vertical cyclone from where the raw material passes before facing the kiln.