Design of a Power Saving Industrial Conveyor System

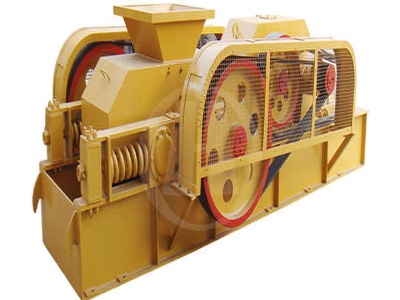

Design a system that start the conveyor belt at low power consumption Increase conveyor system performance in terms of output torque and power Increase average belt life 2. JUSTIFICATION This design will have significance for the industry as its goal is .