jaw crusher adjustment | worldcrushers

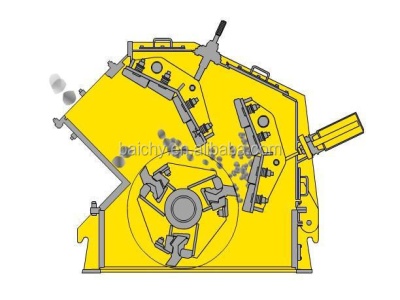

Jaw crusher adjust methods has two ways: jaw crusher wedge iron adjustment and gaskets adjustment to jaw . locking jaw crusher, adjustment and safety devices – Mad Memez 2) shim adjustment, the rear seat and rack thrust plate between the posterior wall, put equal to the thickness of spacer pairs, using the number of shims to change .