The Manufacturing Process of Portland Cement G4 | Manmade ...

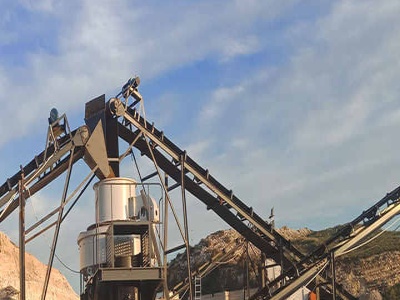

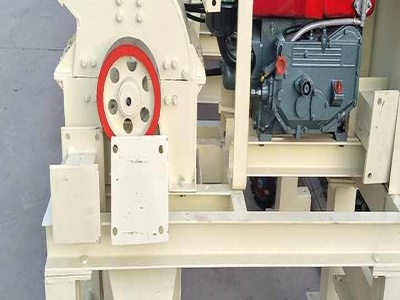

CONCLUSION: The manufacturing of Portland cement required a sequence of process. Roughly, we can convenient the process into 4 main steps : raw material acquisition, rawmix/ clink feed preparation, pyroprocessing, and grinding mill.