Greatwall machinery corporation VRM grinding is as good ...

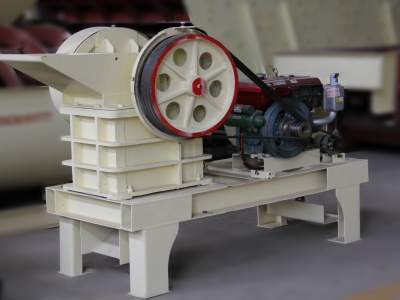

ball mill is higher than that of a vertical roller mill carrying out the same operations by a factor of between and 2, depending on the degree of optimisation of the ball mill. 2. Grinding system options Nowadays, cement producers have the option for using a range of different systems for cement grinding.