The comparison between Gyratory Crusher with Jaw Crusher ...

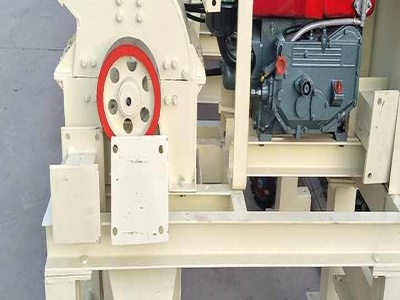

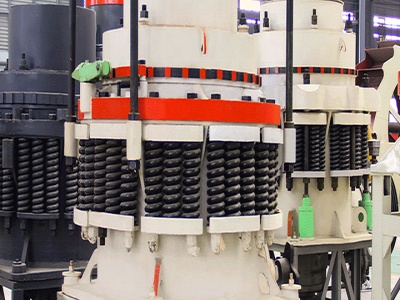

the comparison between gyratory crusher and jaw crusher crushing of gyratory crusher is continuously, so gyratory crusher features high productivity, high reduction ratio, running stable, low consumption, more excellent finished product shape, etc.