Clinker (cement) Wikipedia

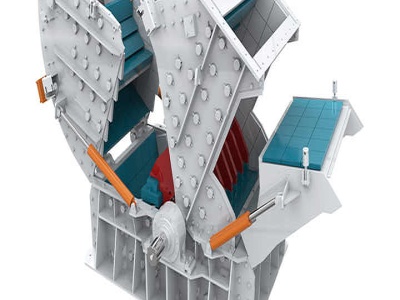

Manufacturers also ship clinker to grinding plants in areas where cementmaking raw materials are not available. Clinker grinding aids. Gypsum is added to clinker primarily as an additive preventing the flash settings of the cement, but it is also very effective to facilitate the grinding of clinker by preventing agglomeration and coating of ...