Cone Crushing Ratio

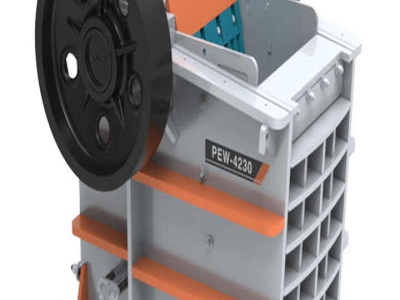

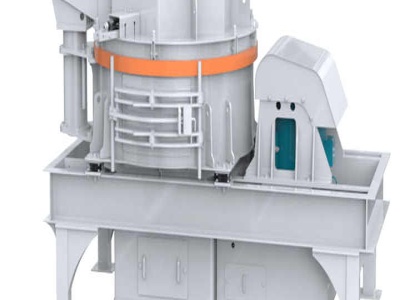

Cone crusher crushing ratio Grinding Mill China. cone crusher manufacturer Jaw crusherMobile crushing . The cone crusher can be used for crushing ores and rocks with medium hardness and above in metallurgy construction road building chemical and silicate industry.