Hot Sale Machinery for Palm Oil Production Process

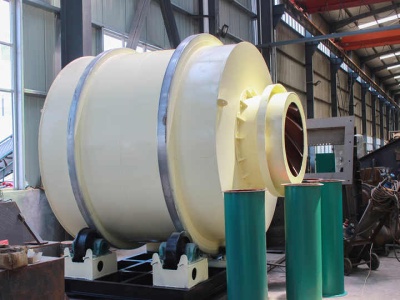

Clarification Station of Palm Oil Mill In complete palm oil productin plant, clarification is the process that ensures removal of all impurities from the crude oil. The sludge is taken different tank chambers and processes to remove particles and other suspended materials.