Composition of cement

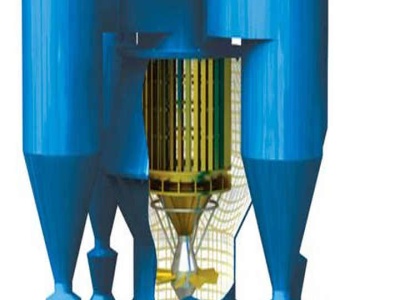

Portland cement is manufactured by crushing, milling and proportioning the following materials: Lime or calcium oxide, CaO: from limestone, chalk, shells, shale or calcareous rock Silica, SiO 2 : from sand, old bottles, clay or argillaceous rock