Vibrating Conveyors

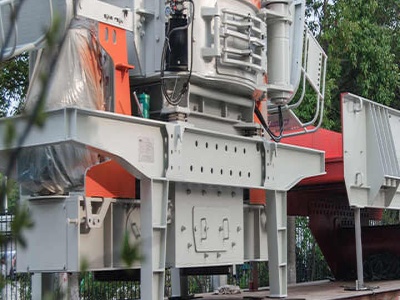

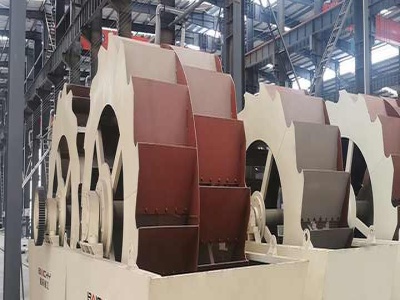

and Coilmount conveyors must be mounted on a concrete foundation at grade level that is suitable to withstand the dynamic loads exerted. Please contact FMC Technologies to confirm actual recommended foundation requirements. Flexmount vibrating conveyors used to reclaim and return steel abrasives to shot blast cleaning system, which