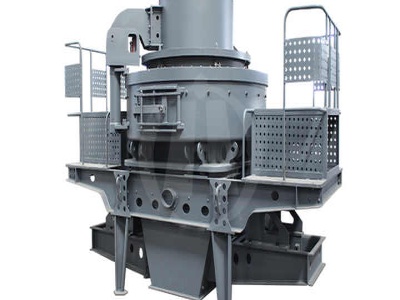

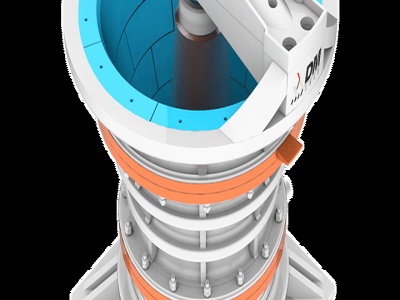

iron ore pellet plant wet grinding process

iron ore pellet wet grinding process iron ore pellet plant process flow chart flow chart of iron ore pellet plant process rajhotel. dry grinding iron ore samassociates. wet grinding process iron ore .