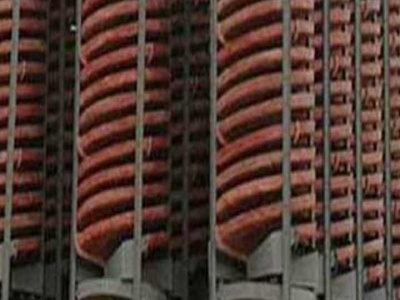

Raw material for mortar

The construction industry is one of the largest purchasers of sand and gravel. Mortar is used for many applications in construction, such as mason, tiling, plastering and grouting. Especially concrete and cement are commonly used in construction and sand and gravel are their main raw materials. We supply a broad range of calibrated sand and gravel for various applications in the construction ...