CHAPTER 4 Steam power plants WIT Press

CHAPTER 4 Steam power plants E. Khalil Department of Mechanical Power Engineering, Cairo University, Cairo, Egypt. Abstract The effi cient utilization of fossil energy in power generation together with low pollution in conventional thermal power plants is a topic that is gaining interest internationally.

![process of coal fired power plant[mining plant]](/vyh0c3w/547.jpg)

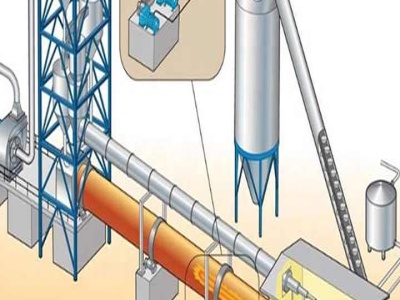

![process of coal fired power plant[mining plant]](/vyh0c3w/114.jpg)