Rock Crusher History Mineral Processing Metallurgy

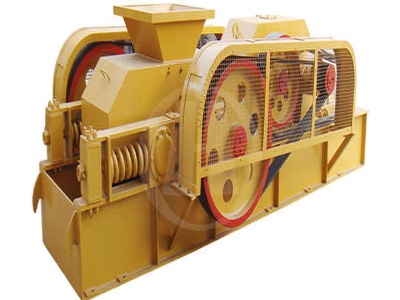

An interesting sidelight of these early days occurred in 1883 when a contest was staged between a Blake jaw crusher and a Gates gyratory crusher. Each machine was required to crush 9 cubic yard of stone, the feedsize and discharge settings being similar.