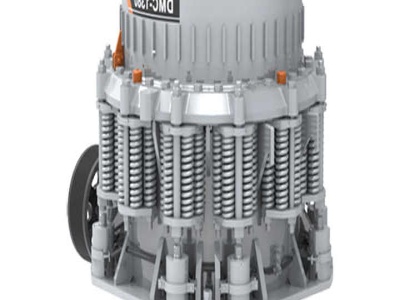

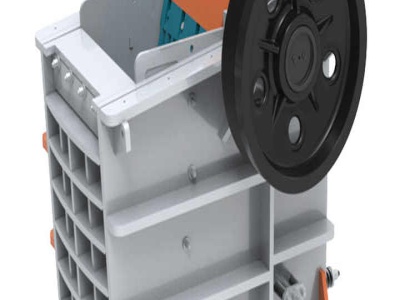

Crushing Equipment

The cone coarse crusher is also called the rotary crusher. The cone crusher for medium and fine crushing is also called the mushroom cone crusher, which is used for crushing various ores and rocks with medium and mediumabove hardness (below 350 MPa), such as calcite, granite, river pebble, dolomite, and glass., cement clinker, iron ore, etc.