Mech Mecca: Power Plants

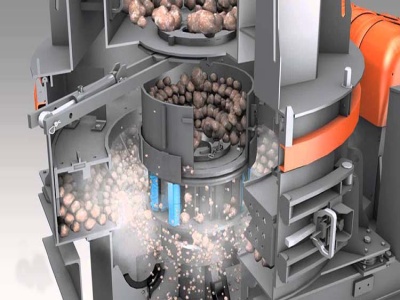

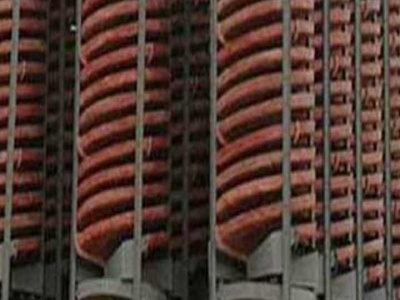

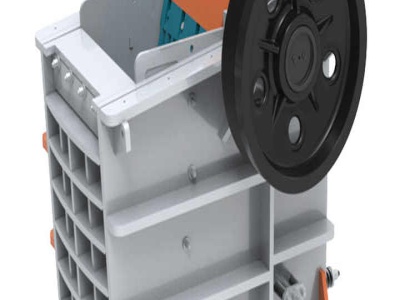

A coal based thermal power plant converts the chemical energy of the coal into electrical energy. ... In coalfired power stations, the raw feed coal from the coal storage area is first crushed into small pieces and then conveyed to the coal feed hoppers at the boilers. The coal is next pulverized into a very fine powder, so that coal will ...