HEAVY DUTY INCLINED VIBRATING SCREENS

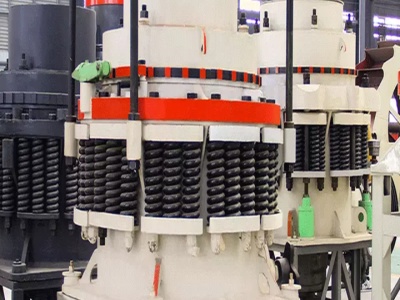

Deister Vibrating Screen is the exclusive "unitized" vibrating mechanism mounted on top of the vibrating frame. The entire vibrating mechanism is a precision constructed, jig assembled unit, which incorporates all the advantages of a twobearing vibrating mechanism and runs in a bath of oil with internal and external labyrinth seals to prevent loss