How Does a Rock Crusher Work? | Sciencing

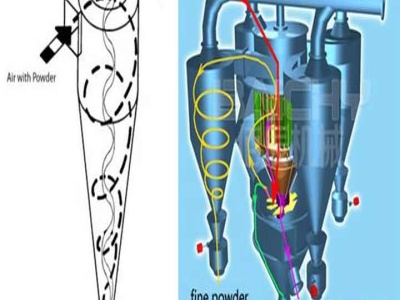

Apr 24, 2017· How Does a Rock Crusher Work? ... Gyratory and cone crushers work in pretty much the same way, although they have slightly different designs. The rock falls into the top of a chamber with a spinning grinder at the bottom. As the rock falls down, it is squeezed between the grinder and the walls of the chamber and crushed. ...