Roller Press_cement production process_Cement epcJiangSu ...

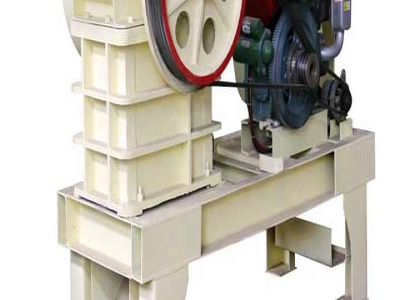

Roller press configuration two solid crushing roller roller surface surfacing of roller surfaceor stud roller surface suitable for feed grain size is less than 40mm finished product sizerequirements of 4 15mm following finely homework. As the cement plant industry mill pre brokencement clinker limestone and composite material; pre crushing grinding steel slag iron oreiron ore industry into ...