Rotary Kilns

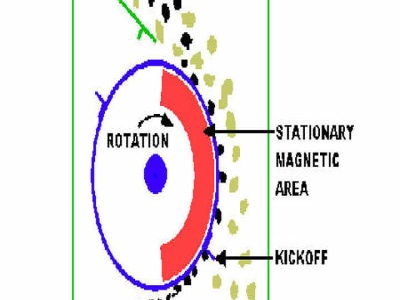

Heat Conduction in Rotary Kiln Wall 187 Radiation Heat Transfer 189 The Concept of Blackbody 190 Radiation Shape Factors 192 Radiation Exchange Between Multiple Gray Surfaces 194 Radiative Effect of Combustion Gases 195 Heat Transfer Coefficients for Radiation in the Freeboard of a Rotary Kiln 196